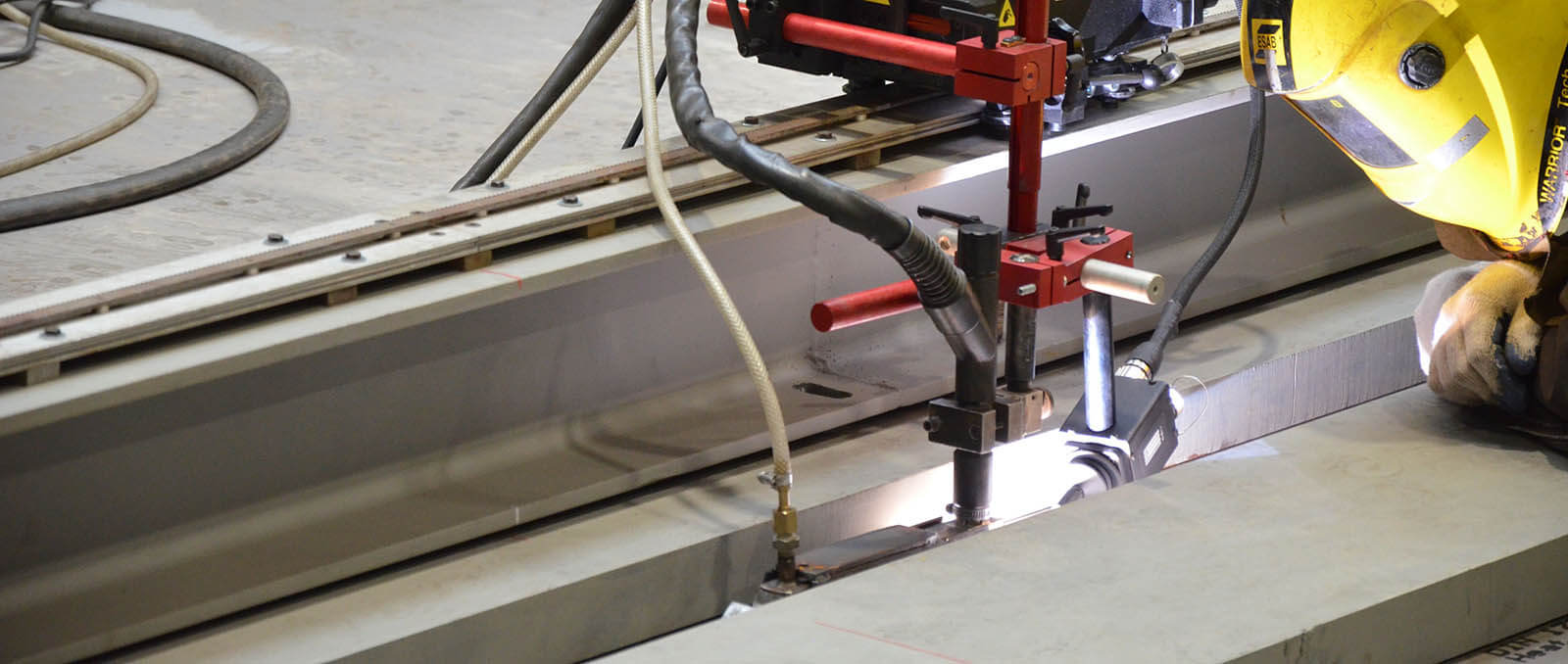

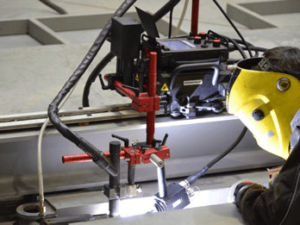

Rail Titan | Modular TIG-MIG-MAG Welding And Cutting Rail Tractor

Rail Titan is a fully modular mechanized tractor that can be custom configured for TIG-MIG-MAG welding, oxy-fuel or plasma cutting, and gouging applications on a flat or curved plate, tube and pipe.

Linear torch oscillator produces straight, triangle, trapezoid and square weld paths. Rail Titan can travel on hi-flex, semi-flexible, rigid, or ring tracks that can be clamped to ferrous materials with magnetic units and to non-ferrous materials by means of a vacuum track system incl. vacuum pump and vacuum units. Rail Titan can work in all welding positions on both ferromagnetic and non-ferromagnetic materials by using rack and pinion drive and various tracks equipped with magnetic or vacuum units.

Applications:

- Trailer manufacturing

- Truck tanks, Oil tanks

- Water storage tanks

- Pressure vessels

- Vessel overlay / hardfacing

- Bridge girders

- Structural steel

- Structural towers

- Panel welding

- Transformers,

- Shipyards,

- Any application demanding long continuous welds

Rail Titan welding tractor can work in all welding positions on both ferromagnetic and non-ferromagnetic materials by using rack and pinion drive and various tracks equipped with magnetic or vacuum units.

Primary features and benefits of Rail Titan welding tractor:

- Suitable for TIG welding (HF resistant)

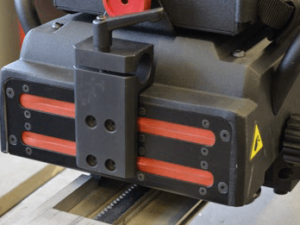

- Robust design with die-cast aluminum housing

- Ergonomic remote control pendant with simple and easy to find control knobs makes adjustments possible without the lifting of the operators welding hood

- Programmable path of stitch welds

- Suitable for a variety of circumferential and irregular surface applications down to min. the radius of 100 mm (4”)

- ¡ Ring tracks on diameters from 200 mm (8”) OD up to 3 m (10 ft) OD

- ¡ Hi-Flex tracks on diameters from 1500 mm (59”) OD upwards

- ¡ Custom rolled tracks on diameters from 3 m (10 ft) OD up to 10 m (32 ft) OD

- ¡ Semi-flexible tracks can be flexed to minimum radius of 5 m (16 ft) without permanent deformation

- Seam tracking enables active compensation of torch position vertically and horizontally with and without oscillation

- A new type of signal sockets/plugs feature increased HF immunity and improved grip for easier tightening & loosening

- Suitable for all welding positions on both ferromagnetic and non-ferromagnetic materials thanks to rack and pinion drive and various tracks equipped with magnetic or vacuum units

- Rail Titan produces consistently high-quality welds and cuts in a fraction of the time required by manual operations

- Wide input voltage range: 100-240V, 50-60Hz 1ph (single phase)